The steel industry remains one of the most energy-intensive manufacturing sectors globally, with coal playing an indispensable role as both a fuel source and reducing agent in blast furnace operations. The efficiency of coal combustion and conversion processes directly impacts energy consumption, production costs, and environmental performance. Central to optimizing these factors is the coal grinding mill – the equipment responsible for transforming raw coal into precisely controlled fine powder suitable for injection into blast furnaces or use in coke ovens.

Proper coal pulverization achieves several critical objectives in steel production: enhanced combustion efficiency, uniform heat distribution, reduced unburned carbon content, and minimized pollutant formation. The particle size distribution, moisture content, and consistency of pulverized coal significantly influence the thermal dynamics of steel manufacturing processes. This article examines the technological advancements in coal grinding equipment and their contribution to sustainable steel production.

Steel production imposes specific demands on coal grinding systems that distinguish them from other industrial applications. The grinding equipment must deliver consistent particle size distribution within tight tolerances, typically ranging from 70-90% passing 200 mesh (74μm) for pulverized coal injection (PCI) applications. This precision ensures optimal combustion characteristics and flame stability in blast furnaces.

Additional requirements include the ability to handle varying coal hardness and moisture content, minimal maintenance downtime, energy efficiency, and compliance with stringent safety standards regarding dust explosion prevention. The grinding system must also integrate seamlessly with drying, classification, and transport components to create a cohesive coal preparation circuit.

Vertical roller mills have emerged as the predominant technology for coal grinding in modern steel plants due to their superior energy efficiency and drying capabilities. VRMs utilize a bed compression principle where material is ground between a rotating table and stationary rollers. This mechanism provides several advantages over traditional ball mills, including lower specific energy consumption (typically 15-30% less), better drying capacity for high-moisture coals, and more compact footprint.

The operational principle involves feeding raw coal onto the rotating grinding table where centrifugal force distributes it outwardly. Hydraulically loaded grinding rollers then compress the material bed, achieving comminution through compression rather than impact. Simultaneously, hot gases introduced through the mill base provide drying action, with the finely ground coal particles being transported upward by the gas stream to a dynamic classifier for size separation.

Although gradually being replaced by more efficient technologies in new installations, ball mills remain in widespread operation, particularly in older steel plants. These rotating cylindrical mills contain grinding media (steel balls) that cascade and impact the coal particles. While ball mills offer simplicity and reliability, they suffer from higher energy consumption, limited drying capacity, and less precise particle size control compared to vertical roller mills.

The specific power consumption of ball mills typically ranges from 18-25 kWh/t, significantly higher than the 10-16 kWh/t achievable with modern VRMs. Additionally, ball mills require auxiliary equipment for drying moist coal, adding to system complexity and energy usage. However, their ability to handle abrasive materials and provide consistent operation with minimal supervision maintains their relevance in certain applications.

Medium-speed mills, including bowl mills and roller-race designs, occupy an intermediate position between high-speed attrition mills and low-speed ball mills. These systems feature rotating grinding elements that crush coal against a stationary race. Their design offers a balance of compact size, reasonable efficiency, and ability to handle a range of coal types.

Bowl mills, in particular, have found extensive application in power generation and some steel plants. They typically operate at 30-100 rpm and incorporate internal classification systems. While generally more efficient than ball mills, they typically cannot match the performance of modern vertical roller mills, especially when processing high-moisture coals or requiring very fine product sizes.

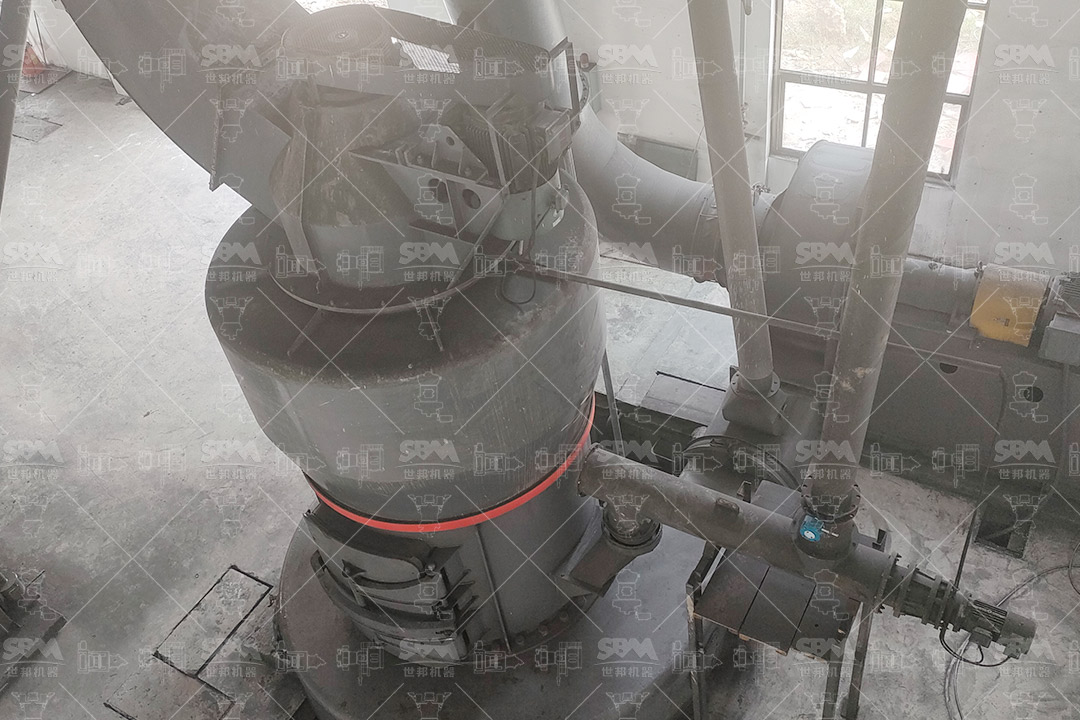

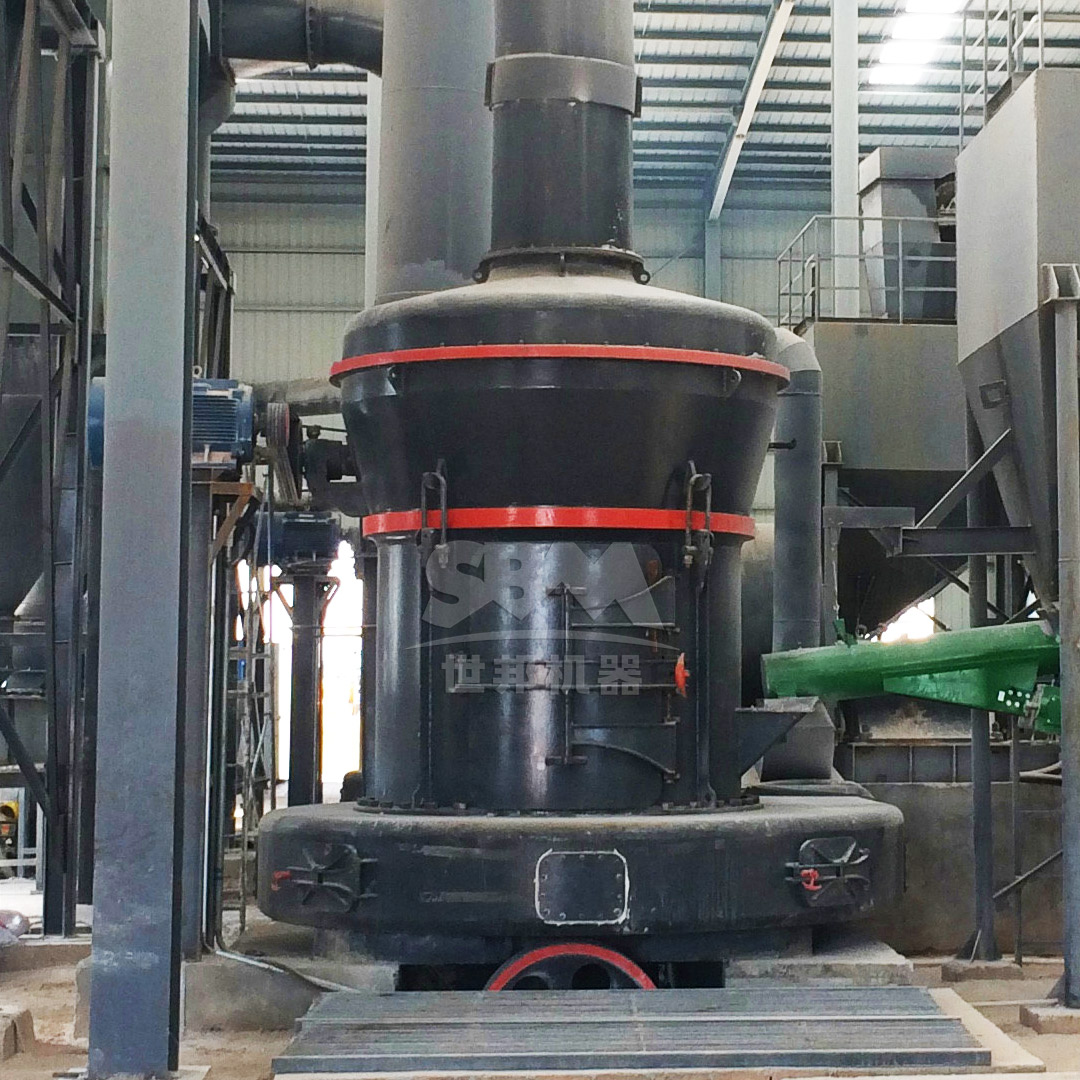

Among the advanced grinding technologies available today, the LM Series Vertical Roller Mill represents a significant advancement specifically engineered for coal grinding in steel production environments. This system integrates multiple functions – crushing, grinding, drying, classification, and conveying – into a single compact unit, offering substantial benefits for steel manufacturers seeking to optimize their coal preparation processes.

The LM Series Vertical Roller Mill features several technological innovations that address the specific challenges of coal grinding:

| Feature | Benefit | Impact on Steel Production |

|---|---|---|

| Integrated drying system | Handles coal with up to 15% moisture without pre-drying | Reduces auxiliary energy consumption |

| Non-contact grinding design | Extended wear part life (3x conventional mills) | Lower maintenance costs and increased availability |

| Dynamic classifier system | Precise particle size control (R0.08mm: 5-20%) | Optimized combustion efficiency in blast furnace |

| Intelligent control system | Automatic adjustment to coal quality variations | Consistent product quality with minimal operator intervention |

The mill’s operating principle begins with raw coal feeding through a central inlet onto the rotating grinding table. Centrifugal force distributes the material across the grinding track where hydraulically loaded rollers apply compressive force. The ground material then moves to the periphery of the table where it encounters the upward gas stream that carries it to the integrated dynamic classifier. Here, precisely controlled particle separation occurs, with oversize particles returning to the grinding zone for further size reduction.

For steel plants requiring high-capacity coal grinding, the LM220M model offers particular advantages with its 35-50 t/h capacity and ability to handle feed sizes up to 50mm. The mill’s 500kW main drive power ensures reliable operation under demanding conditions, while the advanced control system maintains consistent product quality despite variations in raw coal characteristics.

For applications requiring flexibility in product fineness and processing various coal types, the MTW Series Trapezium Mill provides an excellent alternative. This mill combines European grinding technology with innovations in wear protection and energy efficiency, making it suitable for both dedicated coal grinding and multi-material processing facilities.

Key technological advantages of the MTW Series include its curved air channel design that minimizes energy loss during material transport, combined wear plates that reduce maintenance requirements, and integrated cone gear transmission system achieving 98% transmission efficiency. The mill’s internal circulation system enhances classification accuracy while maintaining compact dimensions.

The MTW215G model, with its 15-45 t/h capacity range and ability to produce product fineness from 30-325 mesh, offers steel plants the flexibility to adjust coal specifications according to changing process requirements. The mill’s 280kW main motor power ensures stable operation, while the intelligent control system allows for remote monitoring and adjustment – particularly valuable in integrated steel plant environments.

The optimal particle size distribution for pulverized coal injection (PCI) in blast furnaces typically targets 70-90% passing 200 mesh (74μm), with maximum particle size not exceeding 300μm. This specification balances combustion efficiency, transport characteristics, and grinding energy consumption. Finer grinding improves combustion completeness but increases energy requirements and may enhance explosion risks.

Modern classification systems in advanced grinding mills allow precise control over the product size distribution curve. The LM Series Vertical Roller Mill, for example, can maintain consistent fineness parameters (R0.08mm between 5-20%) through its dynamic classifier system, which adjusts rotor speed in response to feed rate and coal characteristics.

Coal moisture content significantly impacts grinding efficiency, system safety, and combustion performance. High moisture levels (typically above 10-12%) necessitate integrated drying systems to prevent mill choking, reduced throughput, and increased energy consumption. Vertical roller mills inherently provide superior drying capability through their air-swept design and direct contact between hot gases and material bed.

The drying capacity of a grinding system must match the worst-case moisture content expected in the coal supply. For the LM Series Vertical Roller Mill, the integrated hot gas system can handle feed moisture up to 15% without requiring separate drying equipment, simplifying the overall system layout and reducing capital investment.

Coal grinding presents significant wear challenges due to the abrasive nature of mineral matter contained in coal. Modern grinding addresses this through several approaches: specialized wear materials (high-chromium cast iron, ceramic composites), innovative design features that minimize direct contact between grinding elements, and quick-change systems that reduce maintenance downtime.

The LM Series Vertical Roller Mill incorporates multiple wear protection strategies, including hard-faced grinding rollers and table segments, non-contact grinding geometry that minimizes metal-to-metal contact, and modular replacement systems that allow rapid wear part changeout. These features collectively extend maintenance intervals and reduce life-cycle costs.

Energy efficiency represents a critical selection criterion for coal grinding equipment, as comminution typically accounts for a significant portion of the total energy consumption in coal preparation. Comparative studies demonstrate that vertical roller mills consistently outperform alternative technologies, with specific energy consumption typically 25-40% lower than ball mills and 15-25% lower than medium-speed mills.

The energy advantage of VRMs stems from their efficient grinding mechanism (bed compression rather than impact or attrition), integrated classification that minimizes overgrinding, and reduced auxiliary power requirements for ventilation and material transport. For a typical steel plant consuming 200,000 tons of pulverized coal annually, upgrading from ball mills to modern VRMs can yield energy savings exceeding 2,000 MWh per year.

Modern coal grinding systems incorporate comprehensive safety and environmental protection features. Dust explosion risks are mitigated through inert gas blanketing systems, explosion venting panels, and monitoring of oxygen levels and temperature. Environmental performance is enhanced through high-efficiency baghouse filters that achieve dust emissions below 20mg/Nm³ – exceeding regulatory requirements in most jurisdictions.

The LM Series Vertical Roller Mill operates under negative pressure, preventing dust escape during normal operation. Its integrated pulse-jet bag filter achieves filtration efficiency exceeding 99.9%, while the mill’s low-noise design (typically below 80dB) contributes to improved working conditions. These features collectively support steel plants in meeting increasingly stringent environmental and workplace safety standards.

Maximizing equipment availability is essential for steel production continuity. Modern coal grinding mills incorporate condition monitoring systems that track critical parameters including vibration, temperature, pressure differentials, and motor current. Advanced systems utilize machine learning algorithms to detect developing faults before they cause unplanned downtime.

The intelligent control system in the LM Series Vertical Roller Mill continuously monitors operating parameters and can automatically adjust settings to maintain optimal performance as wear parts deteriorate. Remote monitoring capabilities allow technical support teams to diagnose issues and recommend corrective actions without requiring onsite visits, further enhancing system reliability.

Effective wear part management balances replacement costs against the performance degradation that occurs as grinding elements wear. Modern mills feature wear part designs that maintain grinding efficiency throughout their service life, with progressive wear profiles that minimize impact on product quality.

For the LM Series Vertical Roller Mill, the modular roller assembly allows individual rollers to be replaced independently, reducing spare part inventory requirements. The hydraulic system enables in-situ roller positioning adjustments to compensate for wear, extending intervals between major maintenance shutdowns. These features collectively contribute to availability rates exceeding 95% in typical steel plant applications.

The ongoing digital transformation of industrial processes is reaching coal grinding operations, with advanced sensors, data analytics, and connectivity enabling new levels of performance optimization. Future grinding systems will likely feature enhanced digital twins that simulate operational scenarios, predictive maintenance algorithms with improved accuracy, and autonomous adjustment capabilities that respond to changing coal characteristics and downstream process requirements.

Integration with broader steel plant digital ecosystems will allow coal grinding operations to optimize based on real-time blast furnace conditions, energy pricing fluctuations, and production scheduling constraints. These developments promise further improvements in energy efficiency, reliability, and environmental performance.

As the steel industry explores alternative reducing agents and fuel sources to reduce its carbon footprint, grinding equipment must adapt to handle diverse materials including biomass, waste plastics, and hydrogen-based fuels. The flexibility of vertical roller mills positions them well for these emerging applications, with their ability to process materials with varying grindability, moisture content, and combustion characteristics.

Future coal grinding systems may evolve toward multi-fuel preparation centers capable of producing precisely controlled blends of traditional and alternative fuels optimized for specific steelmaking processes. This transition will require grinding equipment with enhanced flexibility, precise control capabilities, and robust materials handling systems.

Coal grinding technology has evolved significantly to meet the demanding requirements of modern steel production. Advanced vertical roller mills, exemplified by the LM Series, offer substantial advantages in energy efficiency, product quality control, operational reliability, and environmental performance compared to traditional grinding technologies. As steel manufacturers face increasing pressure to improve sustainability while maintaining competitiveness, investing in modern coal preparation systems represents a strategic opportunity to reduce operating costs, enhance process stability, and minimize environmental impact.

The continuous innovation in grinding technology, coupled with digitalization trends and evolving fuel strategies, ensures that coal grinding mills will remain critical components in steel production infrastructure for the foreseeable future. Selecting the appropriate grinding technology and implementing it with proper operational and maintenance practices enables steel plants to optimize their energy utilization and contribute to more sustainable manufacturing practices.