The demand for high-performance radiation shielding materials has grown significantly across various industries, including medical, nuclear energy, and aerospace. Barite (barium sulfate) is a key mineral in these applications due to its high density and effective attenuation of gamma and X-ray radiation. However, the effectiveness of barite in shielding materials is highly dependent on its particle size and distribution. Ultrafine grinding technology plays a crucial role in achieving the optimal particle characteristics required for superior radiation protection.

Radiation shielding efficiency is directly influenced by the particle size distribution of the shielding material. Finer particles create more homogeneous mixtures with better packing density, which enhances the material’s ability to attenuate radiation. For barite-based shielding materials, particles in the ultrafine range (D97 ≤ 5μm) provide significantly improved performance compared to conventional ground barite.

Producing high-quality ultrafine barite for radiation shielding applications requires specialized grinding equipment capable of achieving precise particle size control while maintaining consistent product quality. The grinding system must handle the specific characteristics of barite, including its moderate hardness (3-3.5 Mohs) and density (4.48 g/cm³).

| Parameter | Requirement | Importance |

|---|---|---|

| Particle Size (D97) | ≤ 5μm | Optimal radiation attenuation |

| Particle Size Distribution | Narrow | Consistent shielding performance |

| Contamination Control | Minimal iron contamination | Maintains material purity |

| Production Consistency | Stable output quality | Reliable shielding performance |

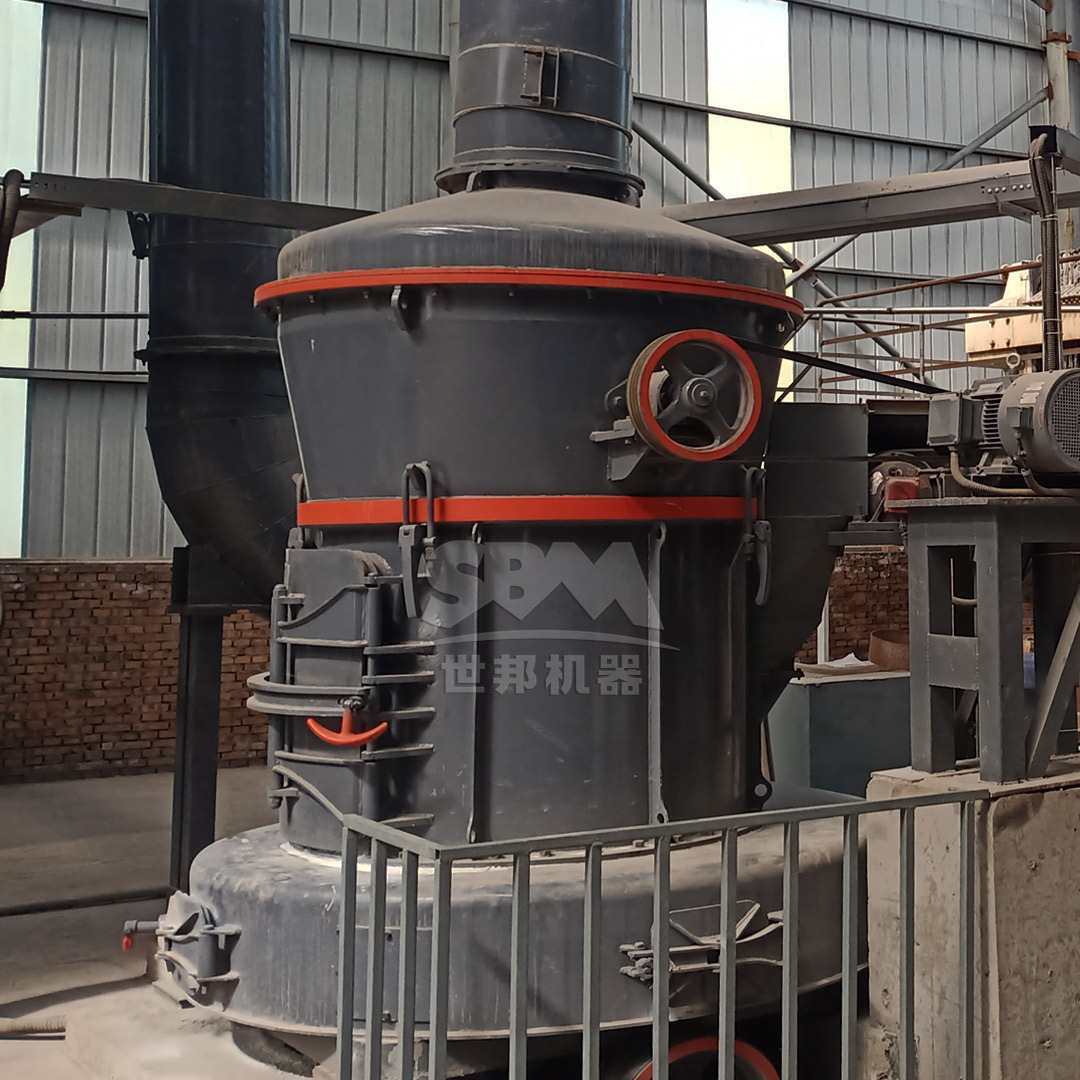

For radiation shielding applications requiring the highest quality ultrafine barite powder, our SCM Ultrafine Mill represents the ideal grinding solution. This advanced mill system is specifically engineered to produce barite powder with the precise particle characteristics needed for superior radiation shielding performance.

The SCM Ultrafine Mill delivers exceptional performance in barite processing through several key technological advantages:

| Model | Capacity (ton/h) | Main Motor Power | Output Fineness | Suitable Application |

|---|---|---|---|---|

| SCM800 | 0.5-4.5 | 75 kW | 325-2500 mesh | Laboratory & Small-scale production |

| SCM1000 | 1.0-8.5 | 132 kW | 325-2500 mesh | Medium-scale shielding materials |

| SCM1250 | 2.5-14 | 185 kW | 325-2500 mesh | Industrial radiation shielding |

| SCM1680 | 5.0-25 | 315 kW | 325-2500 mesh | Large-scale commercial production |

For operations requiring even higher production capacity while maintaining superior product quality, our LUM Ultrafine Vertical Mill offers an excellent alternative. This advanced mill system combines high efficiency with precise particle size control, making it suitable for large-scale barite processing for radiation shielding applications.

| Model | Capacity (t/h) | Main Motor Power | D97 Particle Size | Application Scale |

|---|---|---|---|---|

| LUM1525 | 1.6-11.5 | 220-250 kW | 5-30 μm | Medium to large production |

| LUM1632 | 2-13.5 | 280-315 kW | 5-30 μm | Large-scale industrial |

| LUM1836 | 2.3-15 | 355-400 kW | 5-30 μm | High-volume commercial |

Maintaining consistent product quality is essential for radiation shielding applications. Our grinding systems incorporate advanced control technologies to ensure the barite powder meets the strict requirements for shielding materials.

Modern barite processing for radiation shielding materials must address environmental concerns while maintaining operational efficiency. Our grinding systems are designed with these considerations in mind.

A leading manufacturer of medical radiation shielding components implemented our SCM1000 Ultrafine Mill for processing barite used in protective aprons and room shielding. The results demonstrated significant improvements in product performance:

| Parameter | Before Implementation | After Implementation | Improvement |

|---|---|---|---|

| Particle Size (D97) | 15 μm | 4.2 μm | 72% reduction |

| Shielding Efficiency | 85% at 100 kV | 94% at 100 kV | 10.6% improvement |

| Production Cost | Base | -28% | Significant reduction |

| Material Waste | 8% | 2% | 75% reduction |

The development of advanced radiation shielding materials continues to evolve, with increasing demands for lighter, more effective protection. Ultrafine barite processed through advanced grinding technology will play a crucial role in meeting these future requirements.

The production of high-performance radiation shielding materials requires precise control over barite particle characteristics. Our SCM Ultrafine Mill and LUM Ultrafine Vertical Mill provide the technological solutions needed to achieve the optimal particle size distribution for superior radiation attenuation. With advanced classification systems, energy-efficient operation, and comprehensive quality control features, these grinding systems represent the state-of-the-art in barite processing for radiation shielding applications. As the demand for effective radiation protection continues to grow across multiple industries, the importance of advanced ultrafine grinding technology will only increase, making equipment selection a critical factor in achieving competitive advantage in the shielding materials market.