Barite (barium sulfate) is a critical mineral in the pharmaceutical industry, primarily used as an inert radiopaque agent in diagnostic imaging and as a weighting agent in high-density formulations. The efficacy and safety of pharmaceutical-grade barite are intrinsically linked to its purity and particle size distribution. Micronization, the process of reducing material to fine and ultra-fine powders, is therefore a crucial step in its preparation. This article delves into the technical requirements for pharmaceutical barite micronization and explores the advanced equipment engineered to meet these stringent standards.

Unlike barite used in industrial applications like oil and gas drilling, pharmaceutical-grade barite must adhere to extreme purity and consistency standards as outlined in compendia like the USP (United States Pharmacopeia) and EP (European Pharmacopoeia). Key requirements include:

These requirements necessitate a micronization process that is not only precise but also clean, consistent, and scalable.

The transformation of raw barite ore into a pharmaceutical-grade powder is a multi-stage process.

Raw barite ore is first washed and undergoes primary crushing using jaw crushers or hammer mills to reduce it to a manageable size (typically below 20-50mm). This stage may also involve magnetic separation to remove ferrous impurities.

This is the core of the process, where the pre-crushed material is ground to the desired fineness. The choice of grinding mill is paramount. For pharmaceutical applications where ultra-fine sizes and narrow particle distributions are required, advanced milling technologies are employed. These mills utilize a combination of impact, compression, and attrition forces to achieve micron and sub-micron particle sizes.

Integrated or external classifiers are used immediately after grinding to separate particles based on size. Oversized particles are recirculated back to the grinding chamber for further processing, ensuring only particles within the specified size range proceed. This step is critical for achieving the tight particle size distribution required by the pharmacopeia.

The final micronized powder is collected using highly efficient cyclone separators and pulse-jet baghouse dust collectors. The collected powder may then undergo further processing, such as sterilization, packaging in a controlled environment, and rigorous quality control testing.

Selecting the right milling equipment is the most critical decision in the process. The ideal mill must offer precision, hygiene, efficiency, and reliability.

For the most demanding pharmaceutical applications requiring ultra-fine barite powder, our SCM Ultrafine Mill series represents the pinnacle of milling technology. Engineered specifically for producing powders in the range of 325-2500 mesh (D97 ≤ 5μm), it is an ideal solution.

Why the SCM Ultrafine Mill is suited for pharmaceutical barite:

| Model | Processing Capacity (ton/h) | Main Motor Power (kW) | Input Size (mm) | Output Fineness (mesh) |

|---|---|---|---|---|

| SCM800 | 0.5-4.5 | 75 | ≤20 | 325-2500 |

| SCM900 | 0.8-6.5 | 90 | ≤20 | 325-2500 |

| SCM1000 | 1.0-8.5 | 132 | ≤20 | 325-2500 |

| SCM1250 | 2.5-14 | 185 | ≤20 | 325-2500 |

| SCM1680 | 5.0-25 | 315 | ≤20 | 325-2500 |

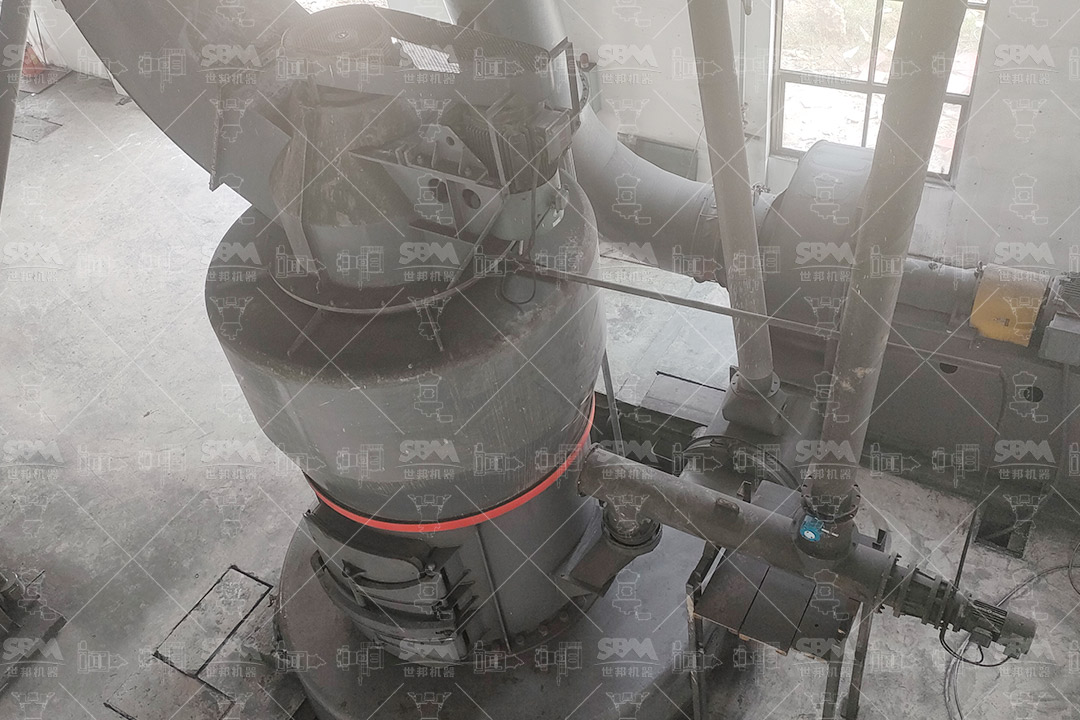

For applications where a slightly coarser grind is acceptable (e.g., 30-325 mesh), or for the initial size reduction stages feeding an ultra-fine mill, our MTW Series Trapezium Mill offers robust performance and high capacity. Its curved air duct and wear-resistant design ensure efficient and low-maintenance operation, making it a reliable workhorse in a complete barite processing plant.

In pharmaceutical manufacturing, the process is as important as the product. Equipment and processes must be validated to prove they consistently produce a product meeting its predetermined specifications and quality attributes. This involves:

The automated control systems and consistent output of modern mills like the SCM series greatly facilitate this validation process.

The micronization of barite for pharmaceutical use is a sophisticated process that demands technology capable of unparalleled precision, purity, and reliability. Moving beyond traditional crushing methods to advanced, integrated milling and classification systems is not an option but a necessity. Equipment like our SCM Ultrafine Mill, designed specifically for ultra-fine, narrow-size-distribution powders, provides a validated path to producing high-quality pharmaceutical-grade barite that meets the rigorous standards of global pharmacopeias, ensuring both patient safety and diagnostic accuracy.