Talc, a hydrated magnesium silicate mineral, plays a crucial role as a functional filler in rubber and plastics manufacturing. Its unique properties—including lamellar structure, chemical inertness, and thermal stability—make it an ideal additive for enhancing product performance. The processing of talc from raw ore to precisely controlled powder involves sophisticated grinding and classification technologies that determine the final material characteristics.

The effectiveness of talc in polymer applications depends heavily on particle size distribution, surface area, and purity. Fine talc powders improve mechanical properties, dimensional stability, and surface finish, while coarser grades serve as cost-effective extenders. This article examines the complete processing chain and highlights advanced equipment solutions for optimizing talc performance in rubber and plastic compounds.

Before grinding, raw talc undergoes several preparation stages to ensure consistent quality. Mining operations extract talc ore, which typically contains 50-90% pure talc along with associated minerals like chlorite, magnesite, and dolomite. The initial processing includes:

Proper beneficiation is critical as impurities can adversely affect polymer properties. Iron-bearing minerals, for instance, may cause discoloration and reduce weathering resistance in plastic products.

The selection of grinding equipment depends on the target particle size distribution and production capacity requirements. Different grinding principles yield powders with distinct morphological characteristics that influence their performance in polymer matrices.

| Grinding Technology | Particle Size Range | Production Capacity | Energy Efficiency | Morphology Characteristics |

|---|---|---|---|---|

| Ball Mill | 45-150μm | High (5-450 t/h) | Medium | Irregular, broad distribution |

| Raymond Mill | 45-325 mesh | Medium (3-22 t/h) | Good | Moderately lamellar |

| Vertical Roller Mill | 30-325 mesh | High (3-250 t/h) | Excellent | Platy, good aspect ratio |

| Ultrafine Mill | 5-45μm (325-2500 mesh) | Medium (0.5-25 t/h) | Very Good | Highly lamellar, narrow distribution |

For rubber and plastics applications where surface area and particle morphology significantly impact reinforcement, ultrafine grinding technologies deliver superior results. The high aspect ratio of platy talc particles improves stiffness, heat deflection temperature, and barrier properties in polymer composites.

Following grinding, precise classification ensures the target particle size distribution. Air classifiers separate particles based on size and density, allowing manufacturers to produce tailored grades for specific applications. For rubber compounds, medium-fine talc (10-45μm) provides optimal balance between reinforcement and processability, while high-performance plastics often require ultrafine talc (D90 < 10μm) for maximum property enhancement.

Surface treatment represents another critical step, particularly for hydrophobic polymers like polypropylene and polyethylene. Organosilanes, stearic acid, or titanate coupling agents improve talc-polymer adhesion, leading to better mechanical properties and reduced moisture sensitivity. The treatment process typically occurs in high-intensity mixers that ensure uniform coating of talc particles.

Modern talc processing demands equipment that combines precision, efficiency, and reliability. The selection of appropriate grinding technology directly impacts product quality, production costs, and environmental compliance.

For manufacturers targeting premium polymer markets requiring ultrafine talc fillers, the SCM Ultrafine Mill represents an optimal solution. This advanced grinding system produces talc powders in the range of 325-2500 mesh (45-5μm) with exceptional particle size control and lamellar structure preservation.

The technological advantages of the SCM Ultrafine Mill include:

The working principle involves centrifugal force distributing material across multiple grinding layers, with progressive size reduction achieved through roller compression. Final powder collection occurs via cyclone separators and pulse dust removal systems, ensuring high recovery rates.

| Model | Processing Capacity (t/h) | Main Motor Power (kW) | Feed Size (mm) | Final Fineness (mesh) |

|---|---|---|---|---|

| SCM800 | 0.5-4.5 | 75 | ≤20 | 325-2500 |

| SCM900 | 0.8-6.5 | 90 | ≤20 | 325-2500 |

| SCM1000 | 1.0-8.5 | 132 | ≤20 | 325-2500 |

| SCM1250 | 2.5-14 | 185 | ≤20 | 325-2500 |

| SCM1680 | 5.0-25 | 315 | ≤20 | 325-2500 |

For rubber and plastic manufacturers seeking to develop high-performance compounds with ultrafine talc, the SCM series provides the precision and consistency required for demanding applications.

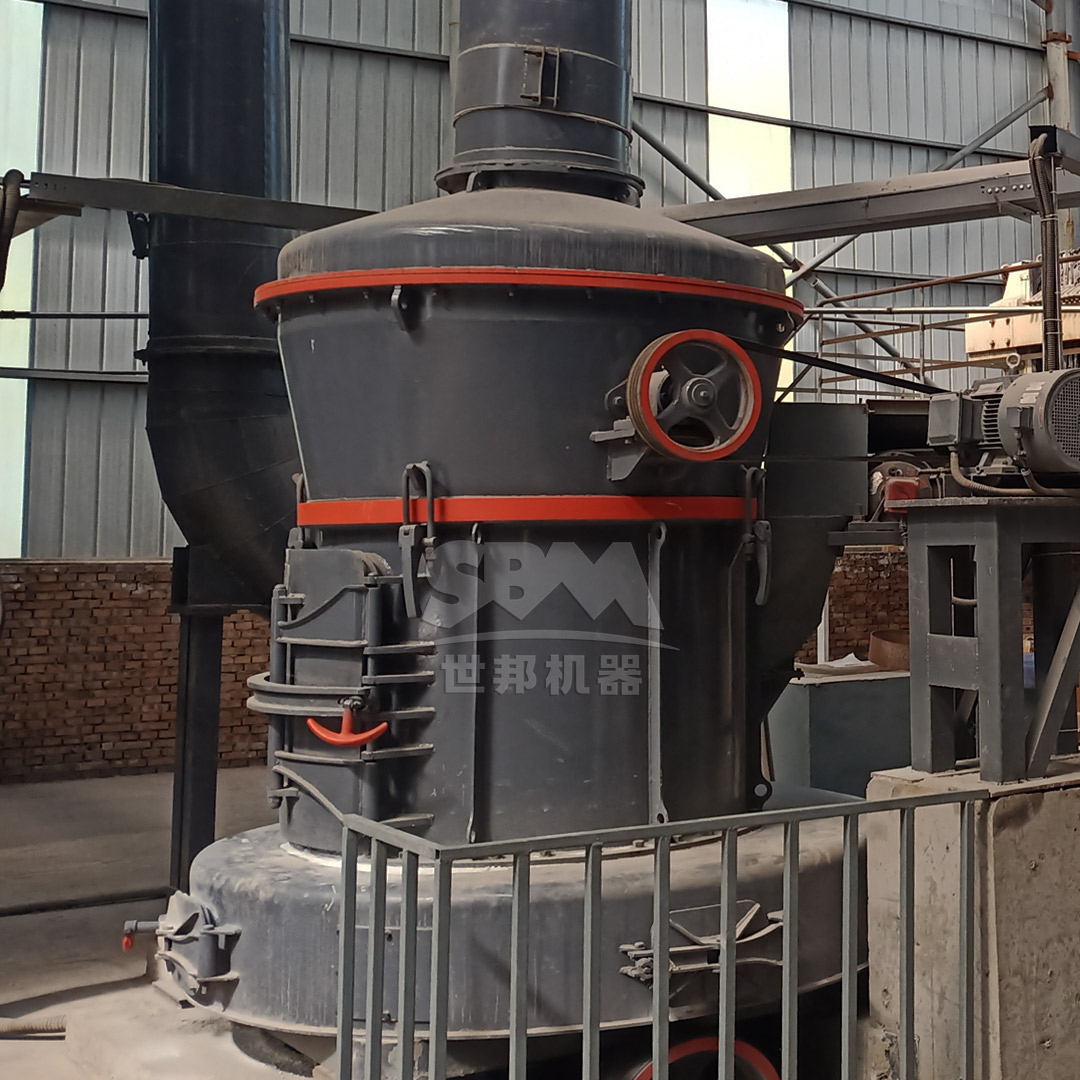

When processing requirements focus on the broader range of talc fillers (30-325 mesh) for standard rubber and plastic products, the MTW Series Trapezium Mill offers an excellent balance of performance and economy. This robust grinding system handles feed sizes up to 50mm with production capacities ranging from 3-45 tons per hour.

Key technological features include:

The operational principle involves main motor-driven grinding rollers revolving around the central axis while simultaneously rotating to generate centrifugal force. Shovel blades feed material between rollers and grinding rings, creating a material bed that undergoes compressive fracturing. Integrated classification systems provide precise control over final product fineness.

The processed talc finds diverse applications across the polymer industry, with specific particle characteristics tailored to enhance particular product properties.

In rubber compounding, talc serves multiple functions:

Automotive rubber goods (hoses, seals, gaskets) typically utilize medium-fine talc (10-45μm) to balance performance and cost. The platy structure of talc provides superior barrier properties in diaphragms and liners.

In plastic formulations, talc enhances numerous properties:

Automotive plastics, household appliances, and packaging materials represent major application areas. Ultrafine surface-modified talc provides the highest performance in demanding engineering plastic applications.

Consistent talc quality is essential for predictable performance in polymer compounds. Key parameters monitored throughout processing include:

Advanced grinding systems like the SCM Ultrafine Mill and MTW Trapezium Mill incorporate automated monitoring and control systems to maintain consistent product quality despite variations in feed material characteristics.

The transformation of raw talc into functional fillers for rubber and plastics requires sophisticated processing technologies that preserve the mineral’s beneficial properties while achieving target particle characteristics. Modern grinding equipment, particularly advanced systems like the SCM Ultrafine Mill for high-value applications and the MTW Series Trapezium Mill for general-purpose use, enables manufacturers to produce talc powders with precisely controlled properties that enhance polymer performance.

As market demands evolve toward higher performance and sustainability, continued advancements in talc processing technology will further expand applications in lightweight automotive components, high-barrier packaging, and specialized industrial products. The selection of appropriate grinding technology remains fundamental to achieving competitive advantage in today’s demanding polymer markets.