The textile industry relies heavily on high-quality mineral fillers and coatings to enhance fabric properties such as weight, opacity, smoothness, and printability. Talc, a hydrated magnesium silicate, is one of the most widely used minerals in textile coatings due to its softness, chemical inertness, and excellent covering power. However, the effectiveness of talc in textile applications is critically dependent on its particle size distribution, purity, and whiteness, all of which are determined by the grinding technology employed.

Selecting the appropriate grinding mill is not merely a matter of cost but a strategic decision that impacts product quality, production efficiency, and operational expenses. An ill-suited mill can lead to inconsistent particle size, excessive energy consumption, high maintenance costs, and ultimately, a substandard textile product. This article provides a comprehensive guide to the key factors involved in choosing the ideal talc grinding mill for textile coating applications, with a focus on achieving the precise fineness and quality required by the industry.

Before delving into mill selection, it is crucial to understand the specific demands that textile coating processes place on talc powder.

For textile coatings, a very fine and tightly controlled particle size is essential. The target fineness typically falls within the range of 325 mesh (45 μm) to 2500 mesh (5 μm). A fine particle size ensures a smooth coating surface, excellent coverage, and improved adhesion to fabric fibers. A narrow particle size distribution is equally important to prevent larger particles from creating imperfections or affecting the hand-feel of the textile.

The inherent whiteness of talc can enhance the brightness of coated textiles. The grinding process must not introduce contaminants that could discolor the talc. Mills must be constructed with materials that minimize iron contamination, which is a common cause of yellowing or graying.

Talc has a low Mohs hardness, which is beneficial for textile handling. The grinding process should preserve this characteristic and not generate excessive hard, abrasive particles that could damage application equipment or the fabric itself.

Textile manufacturing is a high-volume industry. The chosen grinding system must deliver a consistent product quality at the required throughput, often ranging from a few tons to several tens of tons per hour, without frequent fluctuations.

Several types of grinding mills are available on the market, each with its own principles, advantages, and limitations. The following is an analysis of the most common types applied to talc processing.

Ball mills are a traditional grinding system where a rotating cylinder filled with steel balls impacts and crushes the material. While versatile and capable of high capacities, they are generally less energy-efficient for producing very fine powders. The contact between steel media and talc can lead to higher iron contamination, potentially affecting whiteness. They are often better suited for coarser grinding applications outside the optimal range for premium textile coatings.

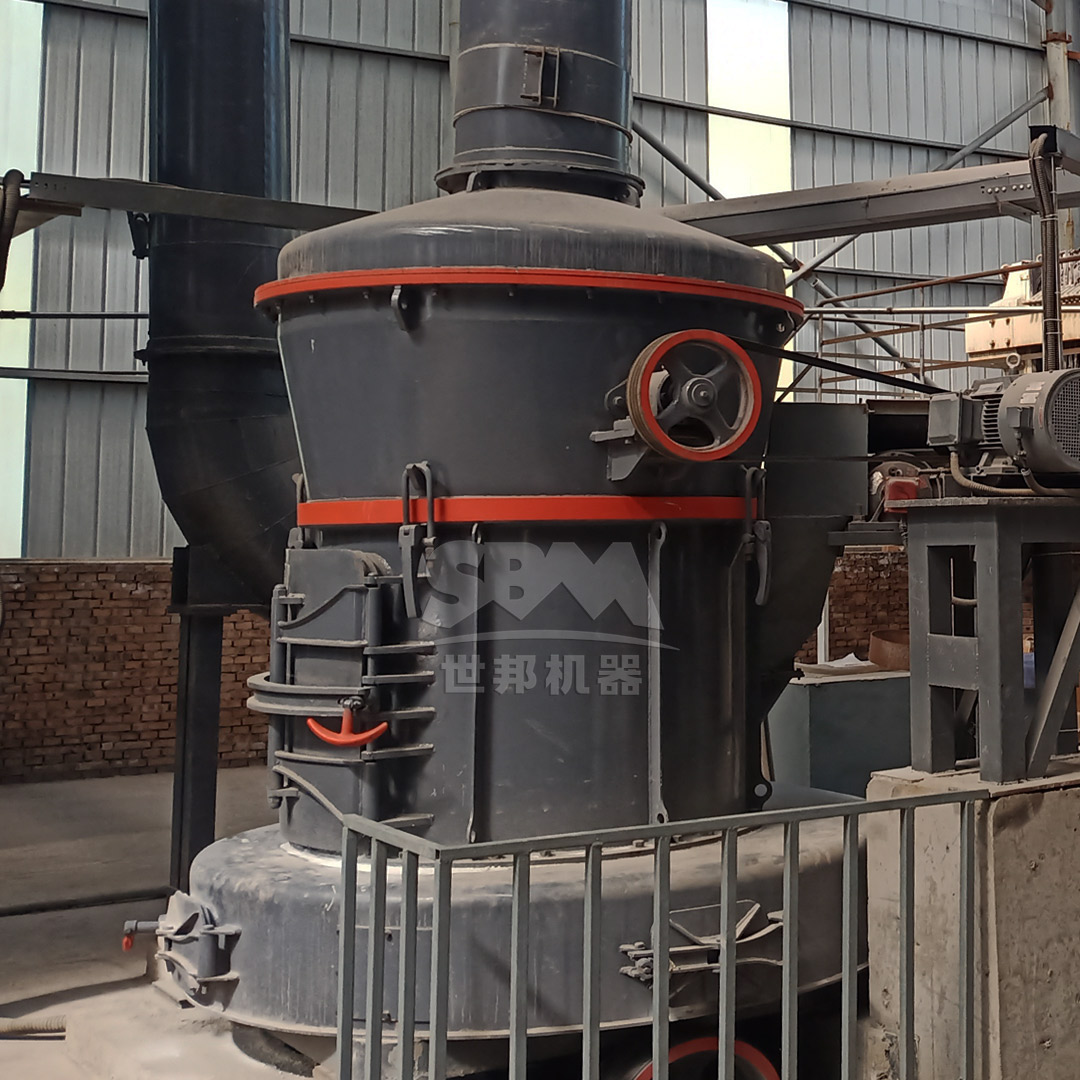

These are medium-speed roller mills that use spring-loaded rollers to crush materials against a stationary ring. They are a robust and cost-effective solution for producing talc in the 30-325 mesh range. For example, the MTW Series Trapezium Mill offers advantages such as a curved air duct for reduced energy loss and wear-resistant components like combined shovel blades. It is an excellent choice for medium-fine talc grinding where the highest ultra-fine specifications are not required. Its capacity range of 3-45 TPH makes it suitable for many mid-sized textile operations.

Vertical Roller Mills (VRMs) use a bed-compaction principle where material is ground between a rotating table and two or more rollers. They are highly energy-efficient, have a small footprint, and offer integrated drying, grinding, and classification. The LM Vertical Mill series is particularly notable for its low operating costs and intelligent control system. It can produce talc powder from 30 to 600 mesh, covering a broad spectrum of textile coating needs. Its fully sealed, negative-pressure operation ensures minimal dust emission, aligning with modern environmental standards.

For the most demanding textile applications requiring talc down to 2500 mesh (5μm), ultrafine grinding mills are the optimal solution. These mills integrate high-intensity grinding with precise air classification.

A prime example is the SCM Ultrafine Mill. This mill is engineered specifically for producing micron-sized powders with a narrow particle distribution. Its core advantages make it exceptionally well-suited for high-grade textile talc:

The SCM series, with models like the SCM800 (0.5-4.5 TPH) up to the SCM1680 (5.0-25 TPH), provides a scalable solution for textile manufacturers focused on producing premium coatings with superior finish and performance.

Making the final decision requires a careful evaluation of several interconnected factors.

| Selection Criterion | Key Questions to Ask | Recommended Mill Type |

|---|---|---|

| Required Fineness | What is the target D97 or mesh size? Is the distribution narrow? | Ultrafine Mill (SCM) for <10μm; VRM (LM) for 45-600μm; Raymond Mill (MTW) for >45μm. |

| Desired Capacity | What is the required tons per hour? Is production continuous? | Match model-specific capacity (e.g., SCM1680 for 25 TPH, MTW215G for 45 TPH). |

| Energy Consumption | What is the kW/h per ton of product? Are there peak demand constraints? | VRMs and Ultrafine Mills generally offer the best energy efficiency. |

| Contamination Risk | How critical is product whiteness and iron content? | Mills with ceramic or special alloy grinding elements (e.g., SCM Mill) are preferable. |

| Capital & Operating Cost | What is the budget for equipment, installation, and maintenance? | Raymond Mills often have lower CAPEX; VRMs/Ultrafine Mills offer lower OPEX. |

| Space & Installation | What is the available floor space and headroom? | Vertical Mills (LM, SCM) have a smaller footprint than horizontal ball mills. |

| Environmental Compliance | What are the local noise and dust emission standards? | Select mills with integrated, high-efficiency baghouse filters and sound insulation. |

A leading textile manufacturer in Asia was facing challenges with the quality of their fabric coatings. Their existing milling system produced talc with a D97 of 20μm, which resulted in a slightly rough hand-feel and limited opacity. They required a finer, more consistent powder to compete in the premium market.

After a thorough technical review, they installed an SCM1000 Ultrafine Mill. The key outcomes were:

Selecting the right talc grinding mill is a pivotal decision that directly influences the quality and cost-effectiveness of textile coatings. The choice must be guided by a clear understanding of the required product specifications, particularly fineness and purity, balanced against production capacity and total cost of ownership.

While Raymond Mills like the MTW Series offer a solid solution for standard applications, and Vertical Roller Mills like the LM Series provide excellent efficiency for a broad fineness range, the pursuit of premium quality textile coatings often leads to the adoption of ultrafine grinding technology.

For manufacturers aiming to achieve the highest standards in fabric finish and performance, the SCM Ultrafine Mill stands out as a superior choice. Its combination of high-precision classification, energy efficiency, and durable, low-contamination design makes it an ideal investment for producing the fine, consistent, and high-whiteness talc that the modern textile industry demands. A careful technical and economic evaluation, potentially involving tests with sample materials, is highly recommended to ensure the selected mill aligns perfectly with specific operational goals.