The production of high-purity quartz powder represents a critical process in numerous industrial applications, particularly in the silicon-based materials industry. Quartz, composed primarily of silicon dioxide (SiO₂), serves as a fundamental raw material for manufacturing solar panels, semiconductors, electronics, optical devices, and advanced ceramics. The quality and properties of the final quartz powder directly influence the performance characteristics of these end products, making the selection of appropriate grinding equipment paramount to achieving optimal results.

Modern quartz processing demands precise control over particle size distribution, chemical purity, and morphological characteristics. The grinding process must not only reduce particle size but also preserve the inherent crystalline structure while minimizing contamination. This requires specialized milling equipment designed specifically for hard, abrasive materials like quartz, which typically has a Mohs hardness of 7.

Quartz grinding presents unique challenges that distinguish it from other mineral processing operations. The material’s high hardness and abrasiveness necessitate robust equipment construction with superior wear resistance. Additionally, the need for high-purity products requires grinding systems that minimize iron contamination, which can adversely affect the electrical properties of silicon-based materials.

Key technical considerations for quartz powder production include:

| Application | Required Fineness | Particle Size Range | Special Requirements |

|---|---|---|---|

| Solar Grade Silicon | D97 ≤ 15μm | 325-800 mesh | Iron content < 100ppm |

| Electronic Encapsulation | D97 ≤ 10μm | 800-1250 mesh | High sphericity |

| Optical Glass | D97 ≤ 5μm | 1250-2500 mesh | No visible impurities |

| Advanced Ceramics | D50 = 1-2μm | 2500+ mesh | Narrow distribution |

The evolution of quartz grinding technology has progressed from traditional ball mills to sophisticated vertical roller mills and ultra-fine grinding systems. Each technology offers distinct advantages for specific applications and production requirements.

Vertical roller mills have emerged as the preferred solution for medium to large-scale quartz powder production. These systems utilize a bed compression grinding principle where material is ground between a rotating table and stationary rollers. The inherent design provides several advantages for quartz processing, including higher energy efficiency, better drying capability, and superior particle size control compared to traditional ball mills.

Modern vertical mills incorporate advanced features such as:

For applications requiring sub-10μm quartz powders, specialized ultra-fine grinding systems are essential. These mills typically employ fluidized bed jet mill principles or advanced mechanical impact mills with integrated high-efficiency classifiers. The ability to produce powders with D97 values as low as 5μm while maintaining narrow particle size distributions makes these systems indispensable for high-value quartz applications.

For operations requiring the highest quality quartz powders with superior particle size control, our SCM Series Ultrafine Mill represents the industry benchmark. This advanced grinding system has been specifically engineered to address the unique challenges of quartz processing, delivering exceptional performance in the production of silicon-based materials.

The SCM Ultrafine Mill achieves remarkable fineness levels of 325-2500 mesh (D97 ≤ 5μm) while maintaining high throughput capacities of 0.5-25 tons per hour, depending on model selection. This combination of ultra-fine grinding capability and substantial production capacity makes it ideally suited for modern quartz processing facilities.

The SCM Ultrafine Mill incorporates several proprietary technologies that provide distinct advantages for quartz powder production:

The grinding process begins with quartz feed material (≤20mm) entering the mill through a sealed feeding system. The main motor drives multiple grinding rings in a layered configuration, generating centrifugal force that disperses material evenly across the grinding track. Progressive compression and shearing forces between the rollers and grinding rings achieve gradual size reduction. Finally, a combination of cyclone collectors and pulse dust removal systems ensures efficient powder collection with minimal product loss.

| Model | Processing Capacity (ton/h) | Main Motor Power (kW) | Feed Size (mm) | Final Fineness (mesh) |

|---|---|---|---|---|

| SCM800 | 0.5-4.5 | 75 | 0-20 | 325-2500 |

| SCM900 | 0.8-6.5 | 90 | 0-20 | 325-2500 |

| SCM1000 | 1.0-8.5 | 132 | 0-20 | 325-2500 |

| SCM1250 | 2.5-14 | 185 | 0-20 | 325-2500 |

| SCM1680 | 5.0-25 | 315 | 0-20 | 325-2500 |

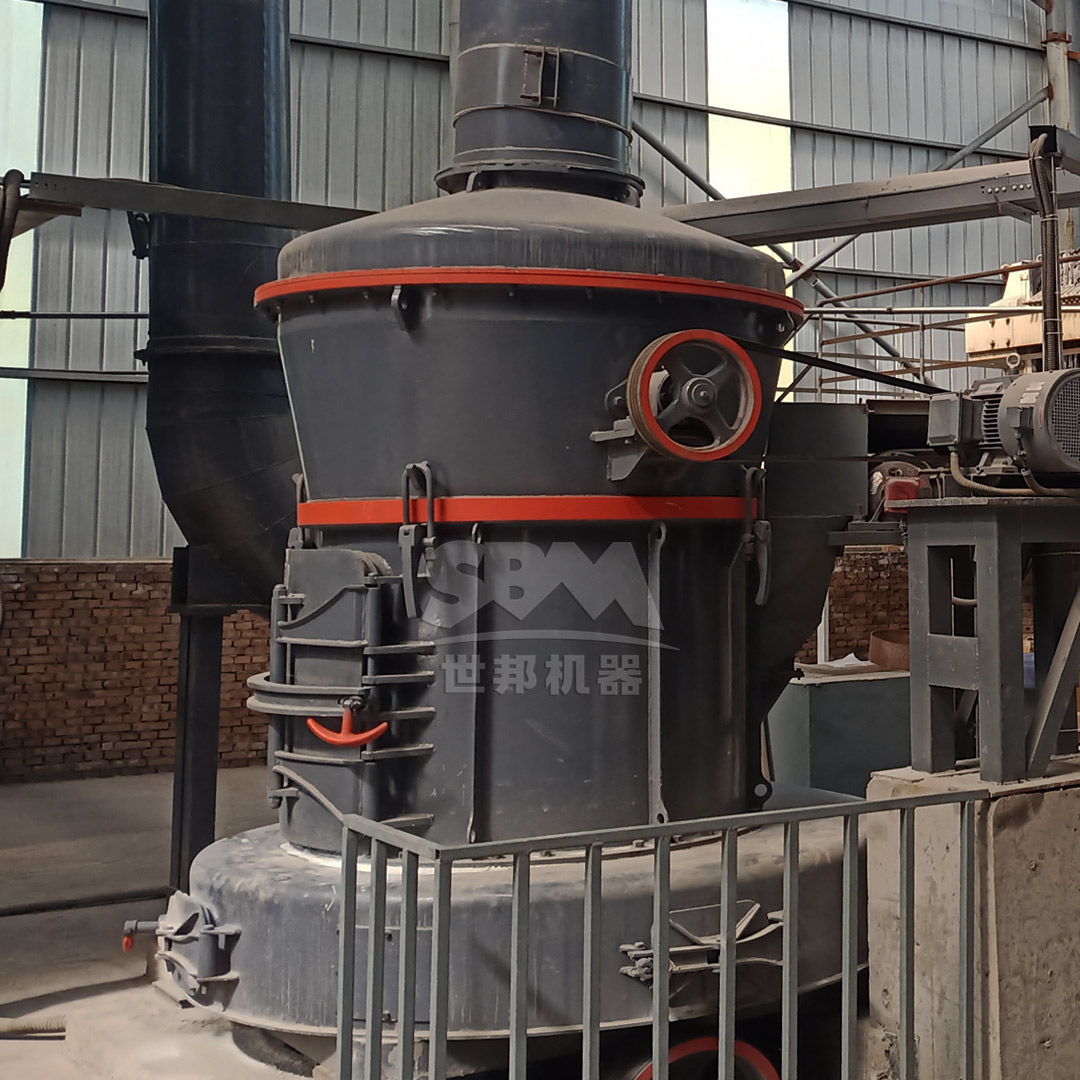

For operations prioritizing high-volume production with excellent cost efficiency, our MTW Series Trapezium Mill delivers outstanding performance in the 30-325 mesh range. This robust grinding system combines European engineering with advanced materials technology to provide reliable, low-maintenance operation for demanding quartz processing applications.

The MTW Series accommodates feed materials up to 50mm in size and delivers throughput capacities from 3-45 tons per hour, making it ideal for large-scale quartz powder production facilities. The mill’s innovative design features several technological advancements specifically beneficial for abrasive materials like quartz.

The MTW Trapezium Mill incorporates multiple proprietary design features that enhance performance and reliability:

The grinding process begins as the main motor drives grinding rollers to revolve around the central axis while simultaneously rotating on their own axes, generating centrifugal force. Specially designed shovels feed material between the grinding rings and rollers, creating a compact material bed where compression grinding occurs. The integrated classification system then precisely controls final product fineness, ensuring consistent quality across all production batches.

Selecting the appropriate grinding technology requires careful consideration of multiple factors, including production requirements, product specifications, and economic parameters. The following analysis provides guidance for technology selection based on specific application needs.

| Technology | Optimal Fineness Range | Capacity Range (t/h) | Energy Efficiency | Investment Level | Best Applications |

|---|---|---|---|---|---|

| SCM Ultrafine Mill | 325-2500 mesh | 0.5-25 | High | Medium-High | High-purity electronic/solar grades |

| MTW Trapezium Mill | 30-325 mesh | 3-45 | Very High | Medium | General industrial grades |

| Ball Mill | 0.074-0.8mm | 0.65-450 | Medium | Low-Medium | Coarse filler applications |

| LUM Vertical Mill | 325-2500 mesh | 1.6-15 | High | High | Specialty high-value applications |

Maximizing the efficiency of quartz powder production extends beyond equipment selection to encompass comprehensive process optimization. Several key factors significantly impact overall operational performance and product quality.

Proper preparation of quartz feed material profoundly influences grinding efficiency and product quality. Optimal practices include:

Fine-tuning operational parameters delivers significant improvements in productivity and product quality:

The quartz powder industry continues to evolve, driven by increasing quality requirements from downstream applications and growing emphasis on sustainable manufacturing practices. Several emerging trends are shaping the development of next-generation grinding technologies.

Advanced automation and control systems represent the future of quartz powder production. Modern mills increasingly incorporate:

Environmental considerations increasingly influence equipment design and operation:

Ongoing developments in materials technology continue to enhance grinding system performance:

The production of high-quality quartz powder for silicon-based materials demands sophisticated grinding technology capable of delivering precise particle size control while maintaining operational efficiency. The selection between ultra-fine grinding systems like the SCM Series and high-capacity options such as the MTW Trapezium Mill depends on specific application requirements, with each technology offering distinct advantages for different production scenarios.

As quartz applications continue to evolve toward finer particle sizes and tighter quality specifications, advanced grinding technologies will play an increasingly critical role in enabling manufacturers to meet these demanding requirements. Through continuous technological innovation and process optimization, modern quartz grinding systems deliver the performance, reliability, and efficiency necessary to support the growing global demand for high-quality silicon-based materials.